3D printing has come a good distance since its invention in 1983 by Chuck Hull, who pioneered stereolithography, a way that solidifies liquid resin into strong objects utilizing ultraviolet lasers. Over the many years, 3D printers have developed from experimental curiosities into instruments able to producing all the things from customized prosthetics to advanced meals designs, architectural fashions, and even functioning human organs.

However because the expertise matures, its environmental footprint has grow to be more and more troublesome to put aside. The overwhelming majority of client and industrial 3D printing nonetheless depends on petroleum-based plastic filament. And whereas “greener” options made out of biodegradable or recycled supplies exist, they arrive with a severe trade-off: they’re typically not as robust. These eco-friendly filaments are likely to grow to be brittle below stress, making them ill-suited for structural purposes or load-bearing elements — precisely the place energy issues most.

This trade-off between sustainability and mechanical efficiency prompted researchers at MIT’s Laptop Science and Synthetic Intelligence Laboratory (CSAIL) and the Hasso Plattner Institute to ask: Is it potential to construct objects which might be largely eco-friendly, however nonetheless robust the place it counts?

Their reply is SustainaPrint, a brand new software program and {hardware} toolkit designed to assist customers strategically mix robust and weak filaments to get the most effective of each worlds. As an alternative of printing a whole object with high-performance plastic, the system analyzes a mannequin by way of finite factor evaluation simulations, predicts the place the thing is more than likely to expertise stress, after which reinforces simply these zones with stronger materials. The remainder of the half will be printed utilizing greener, weaker filament, lowering plastic use whereas preserving structural integrity.

“Our hope is that SustainaPrint can be utilized in industrial and distributed manufacturing settings sooner or later, the place native materials shares might differ in high quality and composition,” says MIT PhD scholar and CSAIL researcher Maxine Perroni-Scharf, who’s a lead writer on a paper presenting the project. “In these contexts, the testing toolkit may assist make sure the reliability of obtainable filaments, whereas the software program’s reinforcement technique may cut back general materials consumption with out sacrificing operate.”

For his or her experiments, the group used Polymaker’s PolyTerra PLA because the eco-friendly filament, and customary or Powerful PLA from Ultimaker for reinforcement. They used a 20 % reinforcement threshold to indicate that even a small quantity of robust plastic goes a good distance. Utilizing this ratio, SustainaPrint was in a position to get better as much as 70 % of the energy of an object printed solely with high-performance plastic.

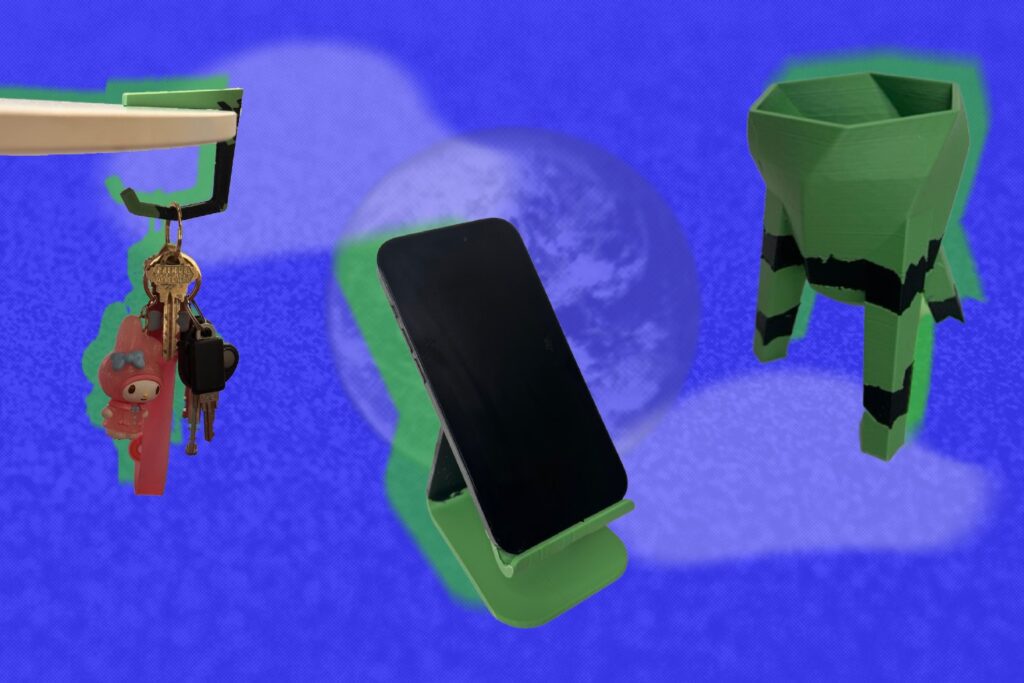

They printed dozens of objects, from easy mechanical shapes like rings and beams to extra useful home items similar to headphone stands, wall hooks, and plant pots. Every object was printed 3 ways: as soon as utilizing solely eco-friendly filament, as soon as utilizing solely robust PLA, and as soon as with the hybrid SustainaPrint configuration. The printed elements had been then mechanically examined by pulling, bending, or in any other case breaking them to measure how a lot drive every configuration may face up to.

In lots of circumstances, the hybrid prints held up almost in addition to the full-strength variations. For instance, in a single check involving a dome-like form, the hybrid model outperformed the model printed solely in Powerful PLA. The group believes this can be because of the bolstered model’s capability to distribute stress extra evenly, avoiding the brittle failure typically brought on by extreme stiffness.

“This means that in sure geometries and loading circumstances, mixing supplies strategically may very well outperform a single homogenous materials,” says Perroni-Scharf. “It’s a reminder that real-world mechanical conduct is stuffed with complexity, particularly in 3D printing, the place interlayer adhesion and gear path choices can have an effect on efficiency in surprising methods.”

A lean, inexperienced, eco-friendly printing machine

SustainaPrint begins off by letting a consumer add their 3D mannequin right into a customized interface. By deciding on mounted areas and areas the place forces shall be utilized, the software program then makes use of an strategy known as “Finite Ingredient Evaluation” to simulate how the thing will deform below stress. It then creates a map displaying strain distribution contained in the construction, highlighting areas below compression or rigidity, and applies heuristics to section the thing into two classes: people who want reinforcement, and people who don’t.

Recognizing the necessity for accessible and low-cost testing, the group additionally developed a DIY testing toolkit to assist customers assess energy earlier than printing. The equipment has a 3D-printable machine with modules for measuring each tensile and flexural energy. Customers can pair the machine with frequent objects like pull-up bars or digital scales to get tough, however dependable efficiency metrics. The group benchmarked their outcomes towards producer information and located that their measurements persistently fell inside one customary deviation, even for filaments that had undergone a number of recycling cycles.

Though the present system is designed for dual-extrusion printers, the researchers consider that with some guide filament swapping and calibration, it could possibly be tailored for single-extruder setups, too. In present type, the system simplifies the modeling course of by permitting only one drive and one mounted boundary per simulation. Whereas this covers a variety of frequent use circumstances, the group sees future work increasing the software program to assist extra advanced and dynamic loading circumstances. The group additionally sees potential in utilizing AI to deduce the thing’s supposed use based mostly on its geometry, which may enable for totally automated stress modeling with out guide enter of forces or boundaries.

3D without spending a dime

The researchers plan to launch SustainaPrint open-source, making each the software program and testing toolkit out there for public use and modification. One other initiative they aspire to deliver to life sooner or later: schooling. “In a classroom, SustainaPrint isn’t only a instrument, it’s a approach to educate college students about materials science, structural engineering, and sustainable design, multi function venture,” says Perroni-Scharf. “It turns these summary ideas into one thing tangible.”

As 3D printing turns into extra embedded in how we manufacture and prototype all the things from client items to emergency tools, sustainability issues will solely develop. With instruments like SustainaPrint, these issues now not want to come back on the expense of efficiency. As an alternative, they will grow to be a part of the design course of: constructed into the very geometry of the issues we make.

Co-author Patrick Baudisch, who’s a professor on the Hasso Plattner Institute, provides that “the venture addresses a key query: What’s the level of accumulating materials for the aim of recycling, when there isn’t a plan to truly ever use that materials? Maxine presents the lacking hyperlink between the theoretical/summary concept of 3D printing materials recycling and what it truly takes to make this concept related.”

Perroni-Scharf and Baudisch wrote the paper with CSAIL analysis assistant Jennifer Xiao; MIT Division of Electrical Engineering and Laptop Science grasp’s scholar Cole Paulin ’24; grasp’s scholar Ray Wang SM ’25 and PhD scholar Ticha Sethapakdi SM ’19 (each CSAIL members); Hasso Plattner Institute PhD scholar Muhammad Abdullah; and Affiliate Professor Stefanie Mueller, lead of the Human-Laptop Interplay Engineering Group at CSAIL.

The researchers’ work was supported by a Designing for Sustainability Grant from the Designing for Sustainability MIT-HPI Analysis Program. Their work shall be introduced on the ACM Symposium on Person Interface Software program and Expertise in September.